The k15 series combines welding/cleaning and cutting functions in one to provide a more efficient and flexible solution to the market, which is lightweight, easy to operate and economical and intelligent. The system comes with a process parameter library for common materials and thicknesses. For different application scenarios, it can easily and quickly replace the corresponding nozzle of the gun head, which is inserted and used immediately, making the tedious processing simple and the processing efficiency is higher

Description

Product description

The k15 series combines welding/cleaning and cutting functions in one to provide a more efficient and flexible solution to the market, which is lightweight, easy to operate and

economical and intelligent. The system comes with a process parameter library for common materials and thicknesses. For different application scenarios, it can easily and quickly

replace the corresponding nozzle of the gun head, which is inserted and used immediately, making the tedious processing simple and the processing efficiency is higher.

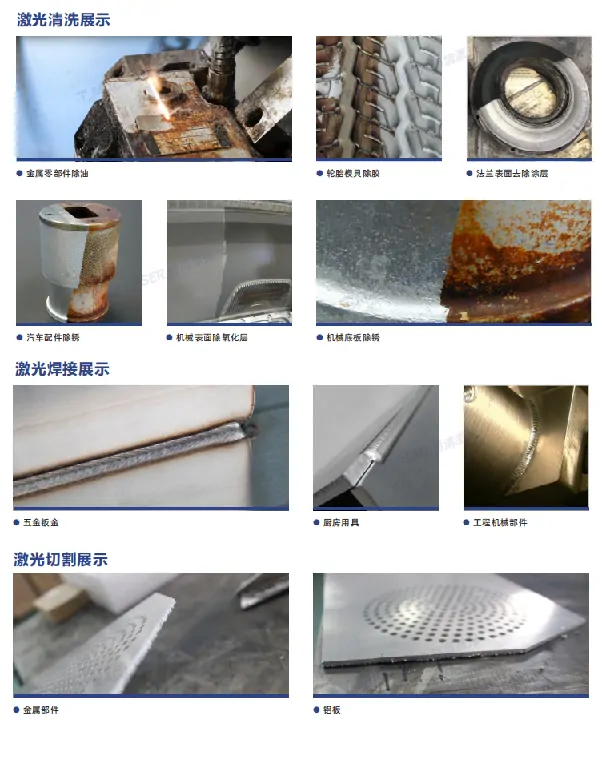

Laser welding cleaning and cutting three-in-one system is our latest launched to support handheld laser welding, laser cleaning, laser cutting three-in-one integrated system.

It can freely switch the working mode according to different application scenarios, providing diversified solutions for different application needs of users. The product covers

welding head/cleaning head and self-developed control system, and sets multiple safety alarms and active safety power off and light off Settings.

Model series | MHJ-B series | ||

Model number | MHJ-1000B | MHJ-1500B | MHJ-2000B |

Laser type | CWX 1000W | CWX 1500W | CWX 2000W |

Output power | 1000W | 1500W | 2000W |

Laser wavelength | 1080+10 nm | ||

Working mode | Continuous/spot welding | ||

Power regulation range | 10 ~ 100% | ||

Fiber core diameter | 25 or 50 | ||

Aiming and fixing | Red light | ||

Fiber length | 12 m | ||

Welding speed | 0 ~ 120 mm/s (customizable) | ||

Applicable thickness | < 3.5mm (depending on material) | ||

Wire feeder | Standard wire feed speed 0.1-6m/min | ||

Feed diameter | 0.8/1.0/1.2/1.6/2.0mm | ||

Cooling mode | water-cooling | ||

Working environment | 10~40°C, humidity 10~85%, no condensation | ||

Operating voltage | 3.5KW | 4.5KW | 6KW |

Operating voltage | 220±20V,AC,PE,50/60Hz | ||

External dimension | 985X395X800mm | ||

Machine weight | About 130kg | ||